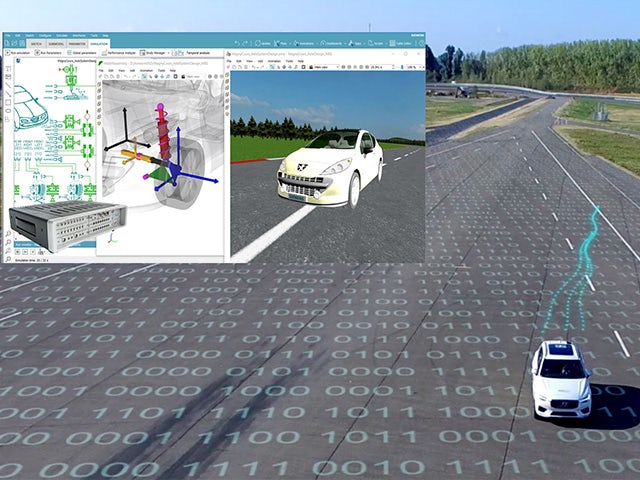

In response to the main market drivers – energy efficiency, safety and performance – many products now include controllers and electronic components that help optimize the product performance or refine its brand character. The widespread use of advanced control systems increases the complexity of product development, simulation and testing.

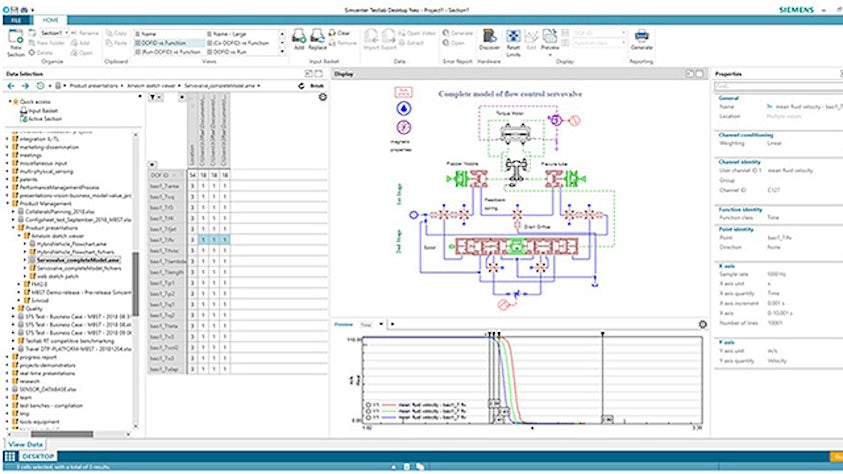

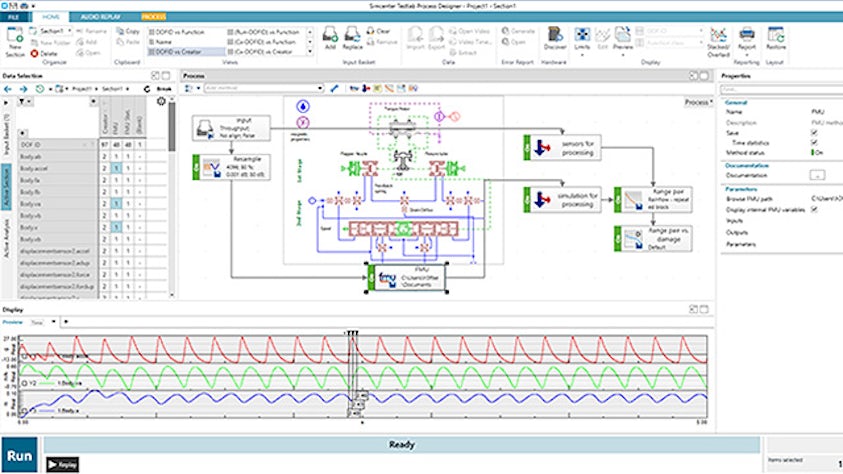

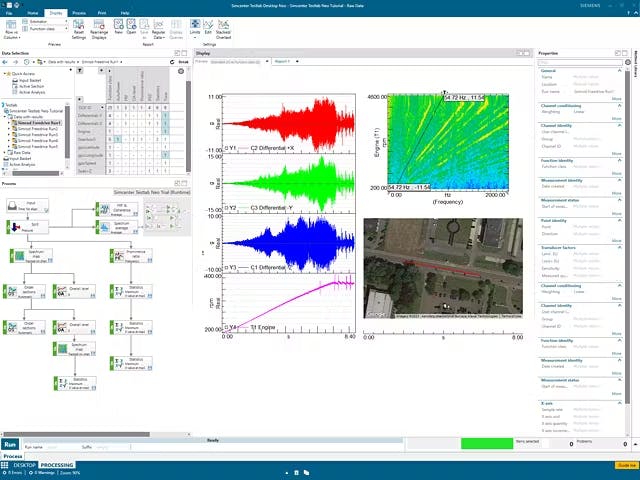

To accelerate system testing at any development stage of the model-based development process, Simcenter extends its portfolio with model-based system testing capabilities. By integrating test and simulation in a single environment for validation of product performance, testing costs and risks can be reduced, productivity increased, and extra system insight gained. Model-based system testing maximizes the consistency of used tools and methods while providing a highly agile mechatronic system engineering environment. It also enables attribute-specific evaluation using virtual models, combined virtual-physical models and physical prototypes.

Efficiently combining test and simulation for model-based development

This unique solution merges physical testing and simulation into one environment to accelerate development by providing augmented engineering insights.