As customer expectations rise, high manufacturing quality is an absolute requirement, regardless of where products are manufactured, distributed and sold. Ensuring quality standards are met through a series of test measurements is a vital part of quality assurance (QA) and production teams. Under the given conditions of the manufacturing environment, quality test systems must generate reliable test results in an economic way with respect to time and test efforts.

With our solutions you can achieve high reliability of the test facility, implement short cycle times and high throughput rate during series production, increase level of automation reducing manual operations and operator errors, combine objective and reproducible pass-fail results with root cause analysis to generate insights for possible intermediate redesigns, and can easily adapt to changing requirements. This systematically improves overall product and manufacturing quality and leads to a reduction in customer complaints. In addition, it supports continuous process improvement by providing valuable input to both the product and production digital twin.

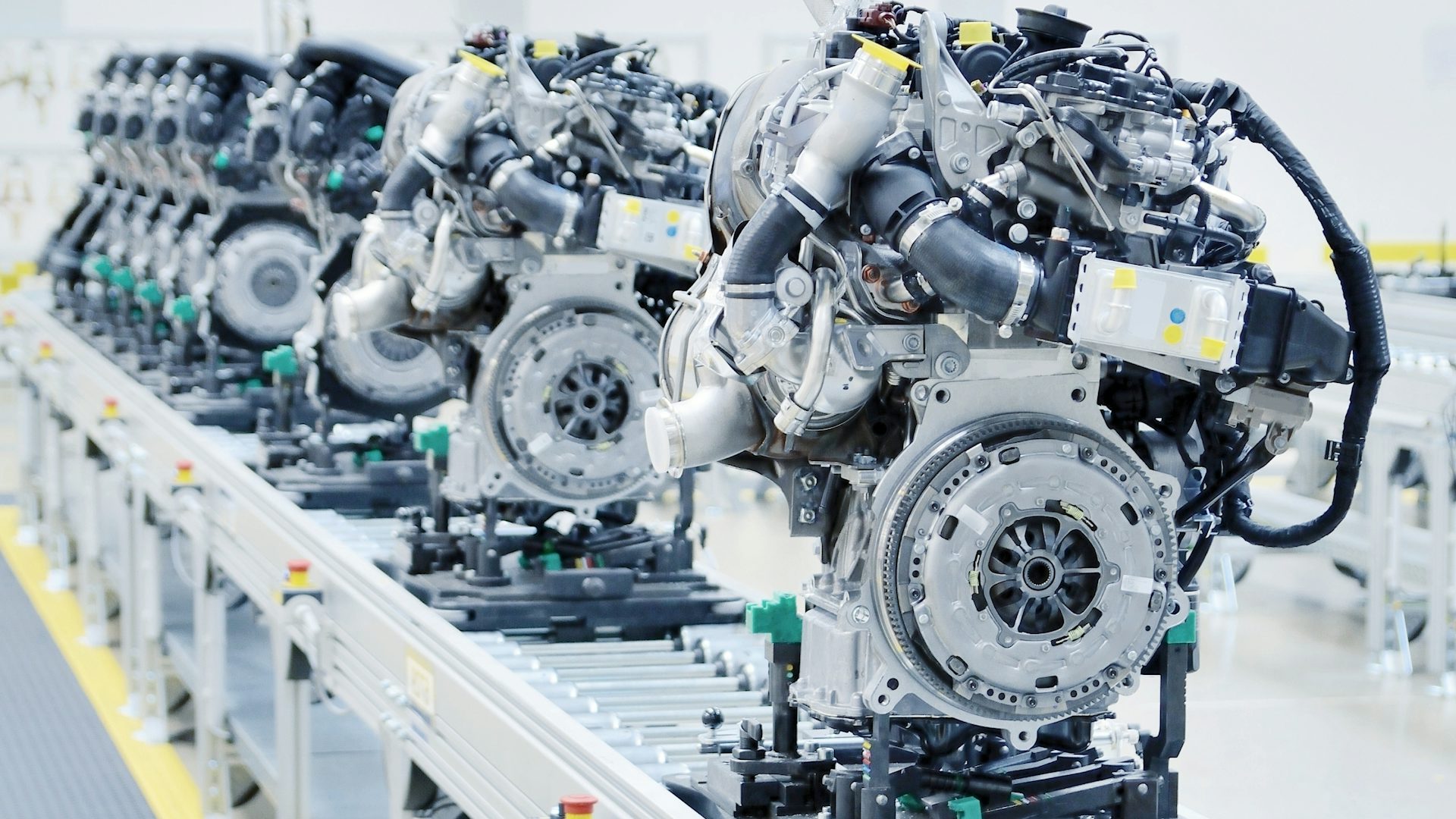

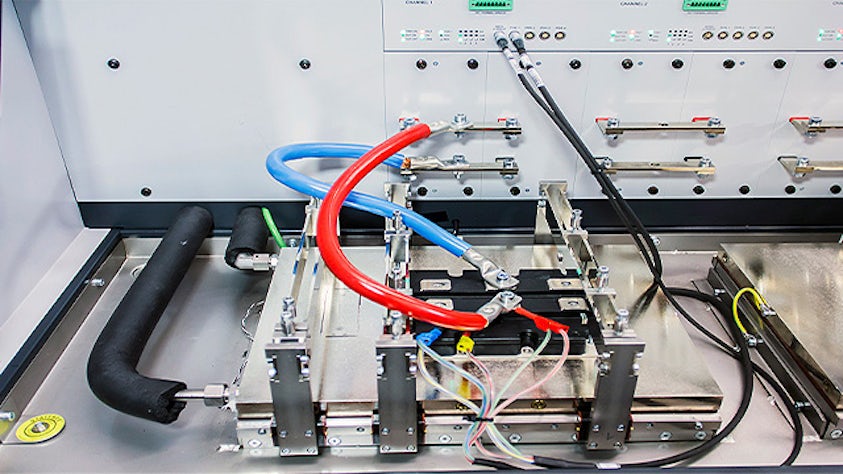

Implement a 100% quality inspection system using end-of-line testing

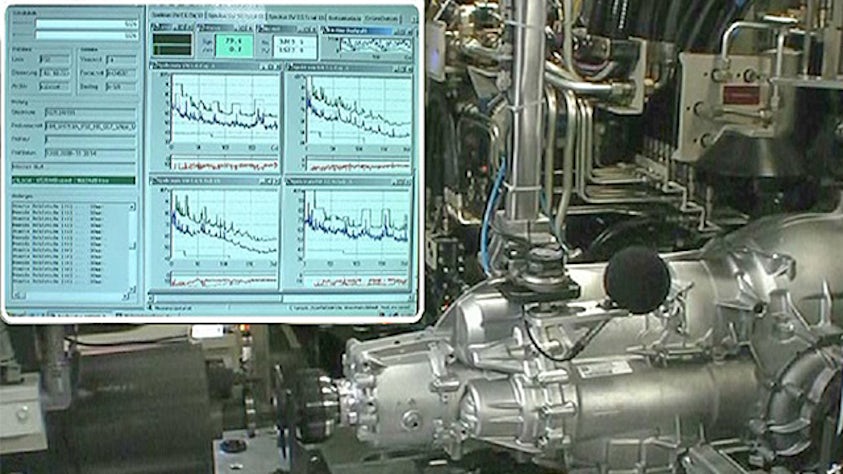

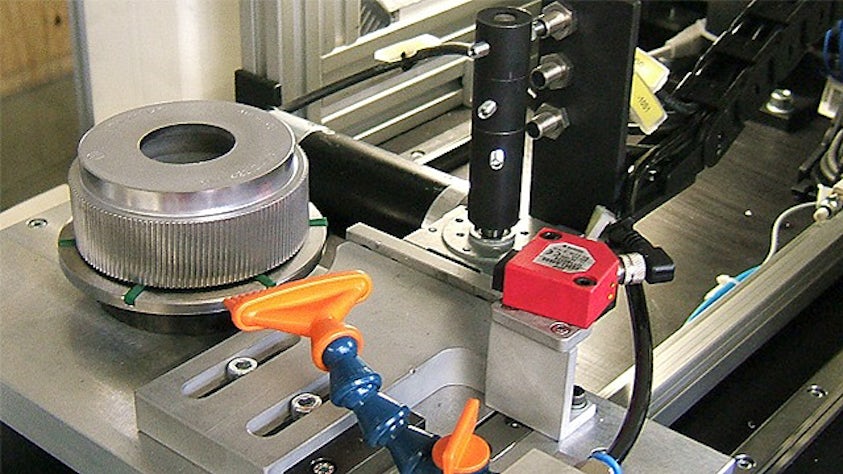

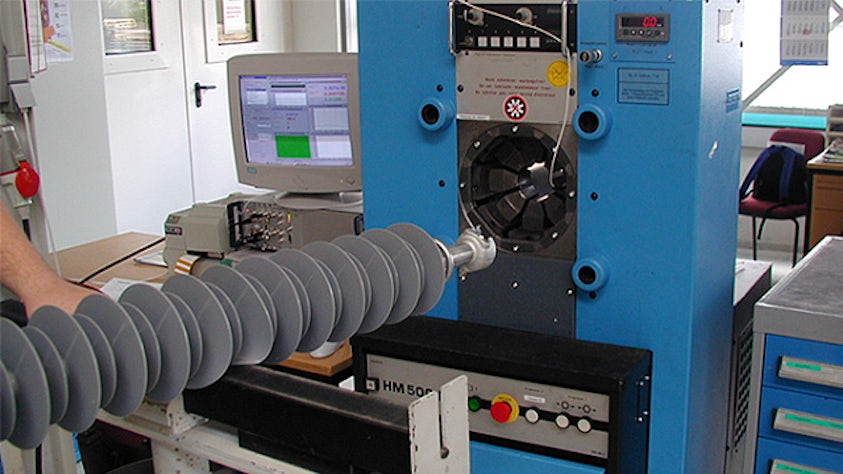

In the automotive sector, end-of-line testing uses vibroacoustic measurements to accurately identify the properties of every produced component and determine if the product has any defect.