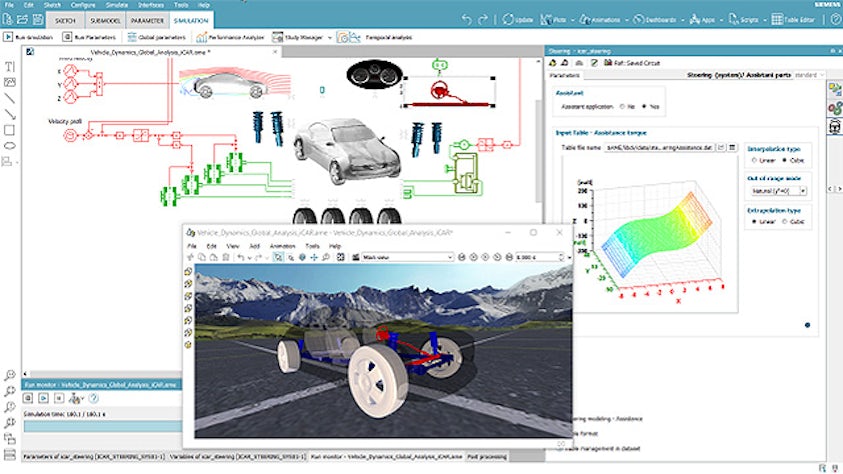

Balance conflicting performance characteristics like comfort and handling, but also stability, agility, drivability and fuel economy. The increasing integration of active controls, together with the use of electrified chassis systems, makes engineering activities even more complex.

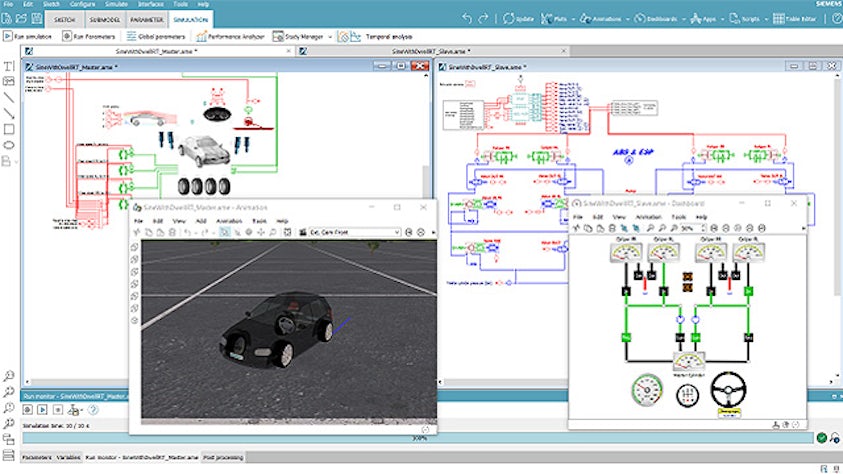

Simcenter provides an integrated approach for developing a vehicle and its chassis components that address the multi-disciplinary nature of all these mechatronic systems thanks to seamless integration and co-simulation capabilities with the controller models. The system simulation approach enables engineers to frontload design decisions for chassis components and their layouts and provides scalable solutions all along the design and validation process, from model-in-the-loop (MiL), software-in-the-loop (SiL) to hardware-in-the-loop (HiL). This helps you reach vehicle system dynamics and chassis component performance targets faster while maintaining (or even improving) your engineering brand values.

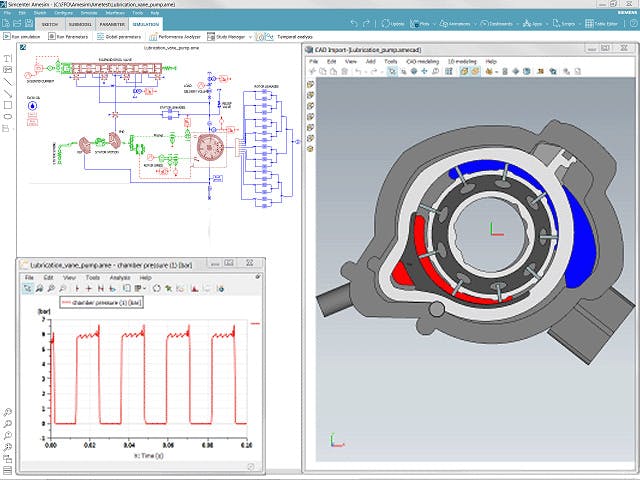

Tire modeling for an outstanding grip on vehicle dynamics

Accurately represent tire behavior throughout the vehicle design process.