Hałas, wibracje i uciążliwość działania to cechy, których doświadczają pasażerowie, które kształtują ich postrzeganie jakości pojazdu. Ich nadmierne nasilenie lub niewłaściwy ton mogą skutkować negatywnymi recenzjami i wpływać na przyszłą sprzedaż. Nic więc dziwnego, że producenci poświęcają tak dużo czasu i zasobów na optymalizację tych parametrów w swoich pojazdach, aby zaoferować klientom lepsze wrażenia. Czy jednak dysponujesz odpowiednim sprzętem i oprogramowaniem do skutecznej oceny parametrów NVH?

Zwiększenie efektywność kampanii pomiarów

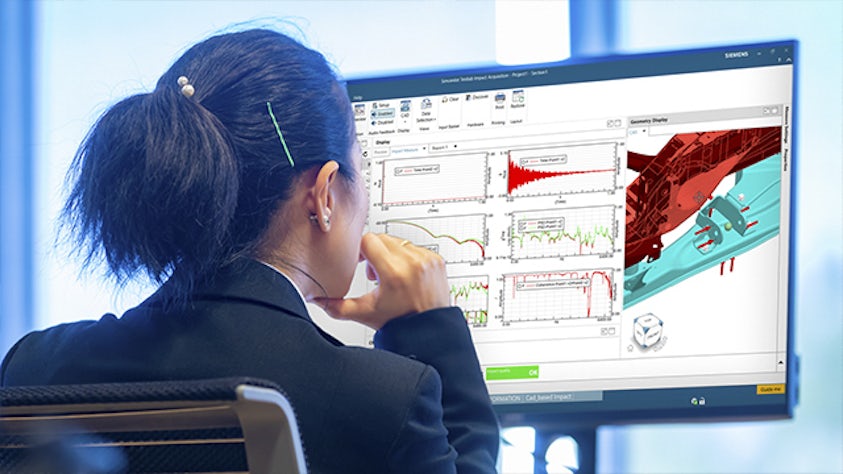

Inżynierowie zajmujący się testowaniem parametrów NVH stoją przed podwójnym wyzwaniem, jakim jest skrócenie czasu wprowadzania produktów na rynek i obniżenie kosztów rozwoju przy jednoczesnym zapewnieniu jakości i kompletności. Ograniczona dostępność prototypów i ilość czasu na przeprowadzanie testów dodatkowo komplikują im pracę, wymagając od nich weryfikowania produktów z większą efektywnością. Mimo tych wszystkich utrudnień muszą przeprowadzać oceny w wielu różnych warunkach testów i zastosowań, zachowując jednocześnie najwyższe standardy.

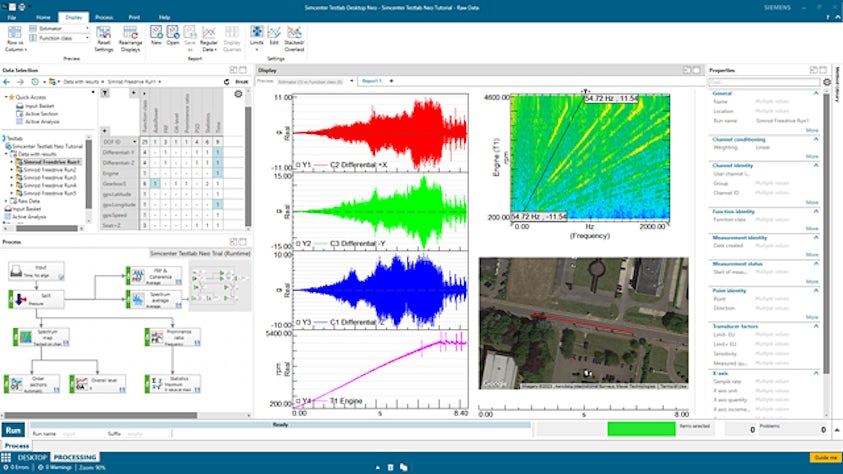

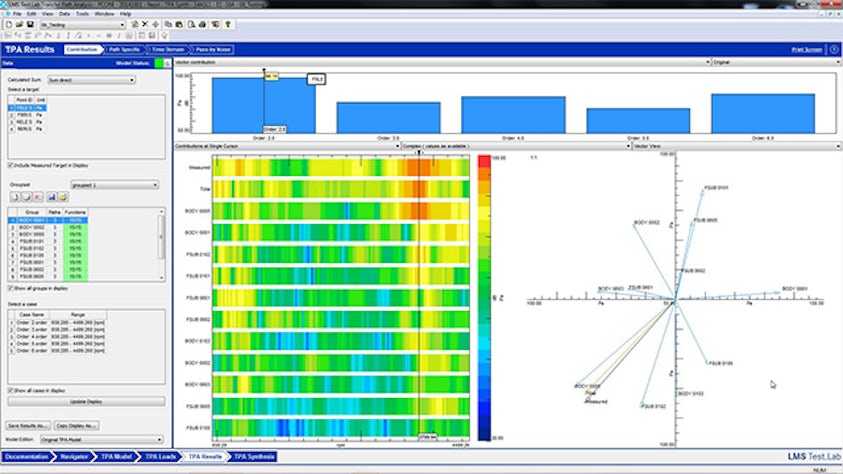

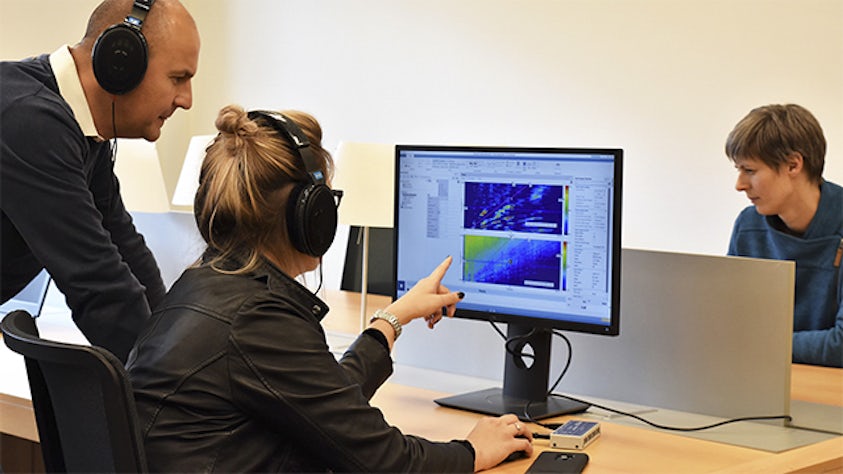

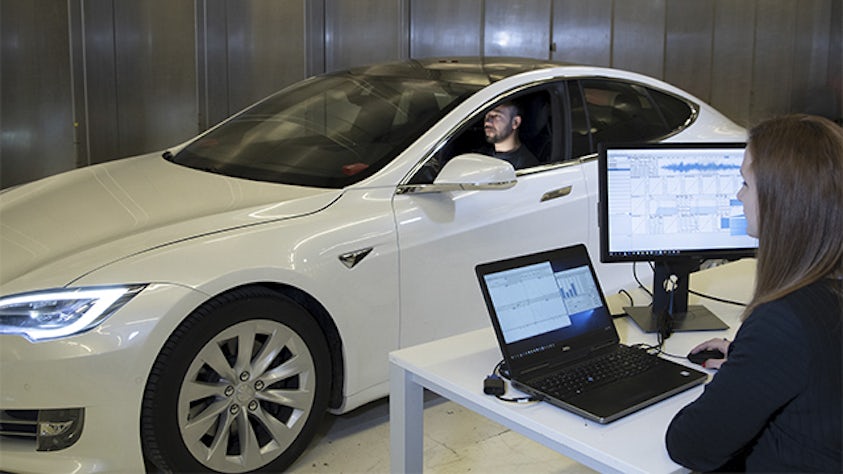

Oprogramowanie Simcenter oferuje zespołom ds. NVH specjalistyczne rozwiązania pozwalające zoptymalizować kampanie testów NVH. Połączenie skalowalnego sprzętu do pozyskiwania danych z oprogramowaniem do pomiarów, przetwarzania i analiz pozwala zwiększyć opłacalność ocen parametrów NVH. Intuicyjne i skalowalne rozwiązania Simcenter do testowania parametrów NVH umożliwiają wydajne pomiary, analizy, raportowanie i udostępnianie danych. Obsługują szeroki zakres działań wykonywanych na różnych etapach cyklu rozwoju, od rozwiązywania problemów po wielokanałowe kampanie testowe.

Najnowsze innowacyjne rozwiązania w obszarze testów parametrów NVH dla branży motoryzacyjnej

Przekonaj się, jak szybko zbadać hałas oraz drgania występujące w warunkach operacyjnych, korzystając z elastycznych metod testów. Zobacz też, jak uzyskać więcej informacji na temat kwestii NVH w krótszym czasie i zagwarantować najwyższą jakość.

-640x360.jpg?auto=format,compress&w=843&q=60)